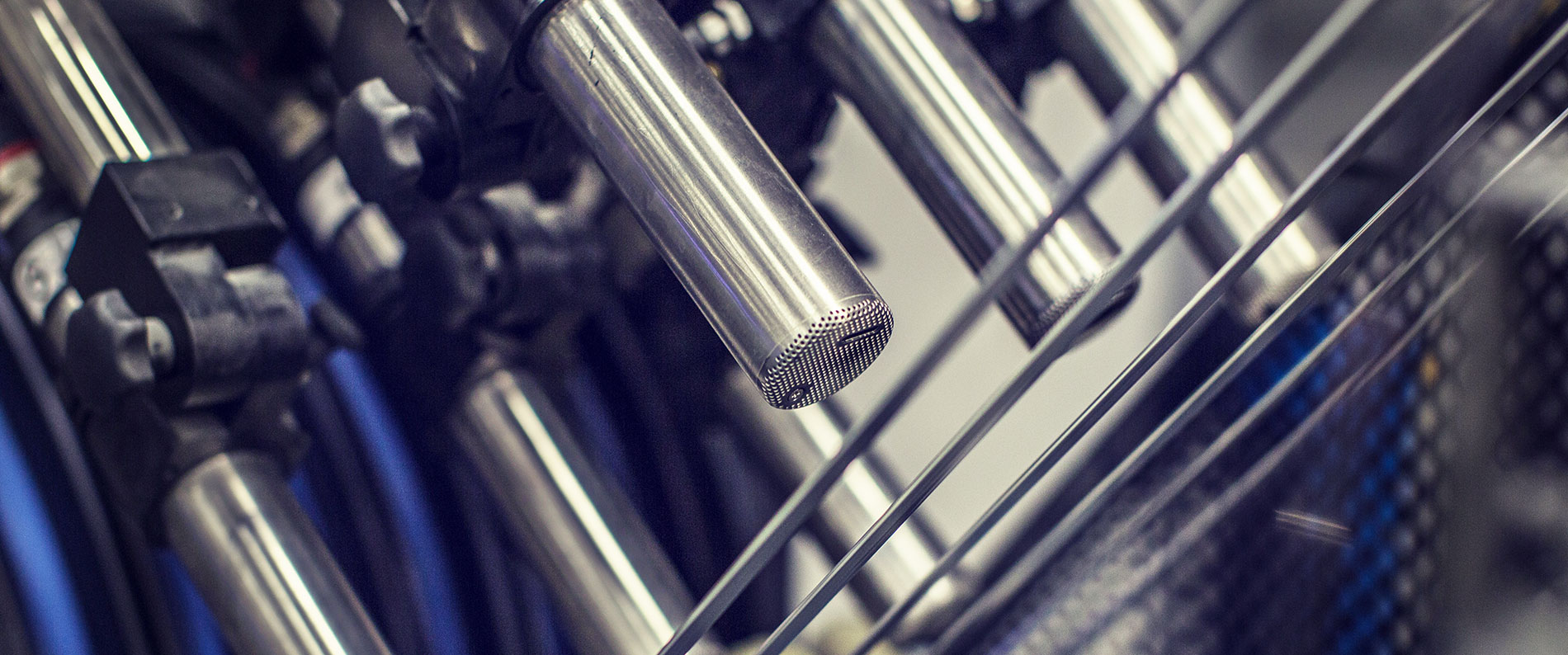

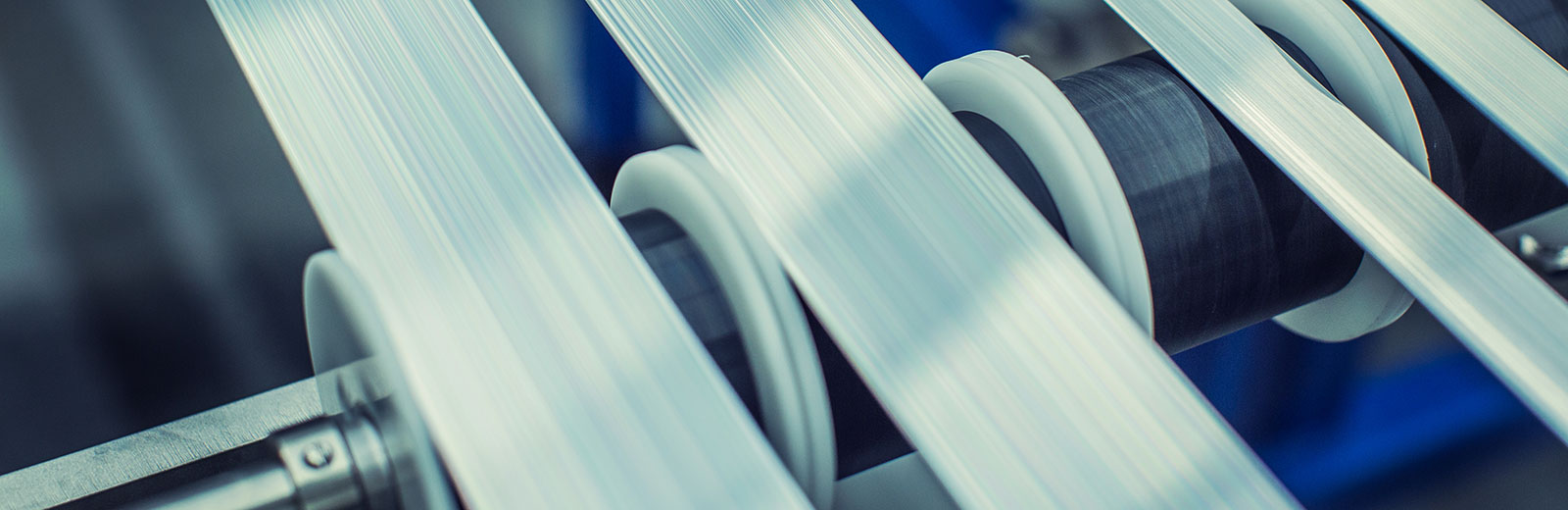

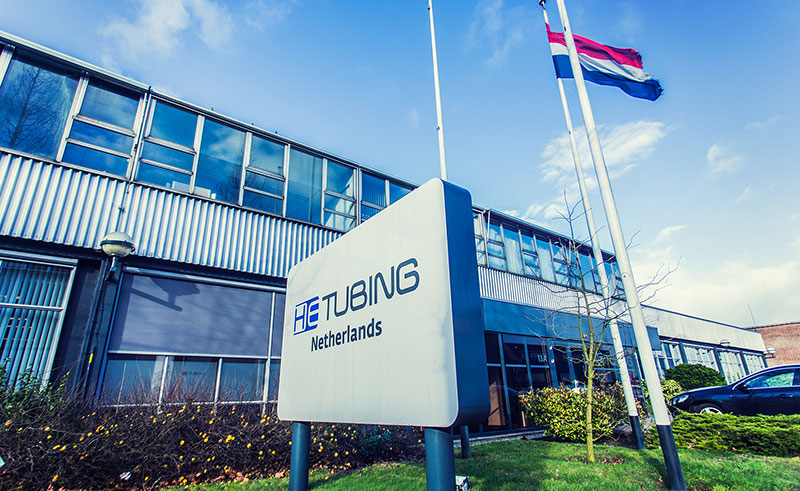

About HE Tubing B.V.

Since 30 years HE Tubing B.V. has been a leading producer of Micro Port Extrusions for heat transfer applications. On the timeline below one can find the history and origin of HE Tubing, our development through the years and HE Tubing’s strategic roadmap.

“With HE Tubing you can rely on more than 30 years of expertise in the field of Micro Multi-Port Extrusions. HE Tubing’s pro-active approach leads to fast responsiveness and flexibility when it comes to quality, delivery performance and overall service.”

HE Tubing has a long history of strong business relations with the world’s major Tier 1 heat exchanger manufacturers supplying the global automakers. As our customer you’ll experience the close co-operation we work in with you (CVM, Customer Value Management) from research and design to production, targeting customized solutions. HE Tubing therefore offers strong support and continuous assistance for present and future projects.

If you choose HE Tubing then you choose a lean though well-organized organisation that stands for quality leadership, customer service, flexibility and competitiveness.

The technical specification ISO/TS 16949:2009 aligns and supersedes existing US, German, French, and Italian automotive quality system standards within the global automotive industry. It specifies the quality system requirements for the design/development, production, installation, and servicing of automotive-related products. The standard is based upon ISO 9001 and was prepared by the International Automotive Task Force (IATF) harmonising the country-specific regulations of Quality-Management-Systems.

The goal of the standard is to improve the system and process quality in order to increase the customer’s satisfaction, to identify problems and risks in the production process and the supply chain, to eliminate the causes of these problems and to examine taken corrections and preventive measures for their effectiveness. The focus lies not on the discovery, but on the avoidance of errors.

ISO 9001 is an international standard for quality management. ISO 9001 can be used to determine whether the organisation is able to meet the requirements of the customers, the rules and regulations applicable for the product and the requirements of the organisation itself. In addition these requirements form a good starting point for the organisation and structure of a quality management system. Simplified the ISO 9001 can be described as:

- Say what you do

- Do what you say

- Prove it

The Plan-Do-Check-Act (PDCA) cycle is the operating principle of all ISO management systems standards, including ISO 9001. By following this cycle, the organisation’s effectiveness can be effectively managed and continually improved.

With the aid of an environmental management system according to the ISO 14001 standard, environmental risks of the business operations can be controlled and can, if possible, be reduced. The ISO 14001 system is created in such a way that it can be integrated seamlessly with ISO 9001. The environmental risk analysis is the most important part of the standard. During this analysis HE Tubing has determined what the environmental risks are for all forms of possible pollution by the company, directly or indirectly. Based upon this analysis the control measures are adopted, which are incorporated in the environmental management plan.

Meet HE Tubing at the trade fairs.

Meet HE Tubing at the next trade fairs